|

JSC "STCD" performs a full range of electric work for electric power generation, transmission and consumption facilities.

WORK PREFORMED

- Pre-project inspection.

- Development of requirements specifications / initial technical requirements.

- Development of design specifications and estimates.

- Development of detailed design.

- Development of design and operational documentation.

- Manufacture and supply of protection, monitoring and control systems and other automation systems.

- System integration of various microprocessor-based units and systems.

- Programming and parameter setting of microprocessor-based equipment.

- Execution of various tests.

- Installation supervision.

- Pre-commissioning activities.

DESIGN ENGINEERING

JSC "STCD" offers full range of electrical equipment design engineering activities including:

- Pre-project inspection;

- Development of engineering design;

- Development of requirements specification;

- Feasibility study;

- Development of detailed design;

- Development of design specifications and estimates.

MANUFACTURE AND SUPPLY

Delivery Options subject to the Customer Demands:

1) manufacture and supply of turnkey relay protection, monitoring and control systems (system solutions);

2) manufacture and supply of cabinet equipment.

On the basis of the functional feature the equipment to be supplied is classified as:

- server cabinets;

- protection, monitoring and control cabinets;

- electric meter cabinets;

- network equipment cabinets;

- main supervisory device cabinets;

- workstations;

- local control panels (including those equipped with touch-screen);

- monitoring and control panels;

- group displays.

SYSTEM SOLUTIONS

The following basic options of system solutions are offered to the Customer depending on the automation level and tasks:

- BASIC

- STANDARD

- PROFESSIONAL

Basic system solutions Basic system solutionsBASIC SYSTEM SOLUTIONS

The solution is suitable for monitoring small (simple) items:

- A small number of field level microprocessor-based units (up to 25 units);

- Common communication protocol at all system levels (IEC 61850 or IEC 60870-5-104);

- Simplified network architecture;

- No expensive controllers and SCADA-server.

STANDARD SYSTEM SOLUTIONS

Standard system solutions Standard system solutionsThe value for money makes this solution optimal for medium-size items:

- Increased number of microprocessor-based field-level units (up to 250 units);

- Increased speed and reliability due to using dedicated redundant servers of SCADA-system;

- Increased number of protocols and variability of communication environment;

- Field level network architecture is the dual optical ring.

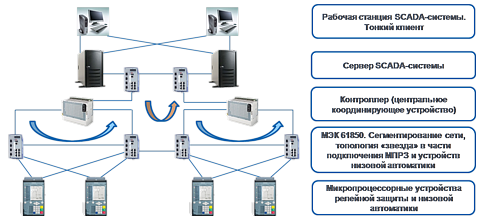

PROFESSIONAL SYSTEM SOLUTIONS

Professional system solutions Professional system solutionsIf the key criteria are reliability, response speed and service life, this solution is absolutely necessary:

- Increased number of field level microprocessor-based units (up to 500 units);

- Increased speed and reliability due to using dedicated redundant servers of SCADA-system;

- Increased network segmentation;

- Application of controller level (main supervisory devices);

- Increased number of protocols and variability of communication environment;

- “Star” network architecture of field level.

SYSTEM INTEGRATION

System integration services include:

- Preliminary integrated tests of microprocessor-based equipment at own test grounds;

- System integration of various microprocessor-based units and systems;

- Technical support of pre-commissioning;

- Expert review of malfunction causes / software-hardware interaction.

PROGRAMMING/PARAMETER SETTING OF INDUSTRIAL CONTROLLERS, MICROPROCESSOR-BASED UNITS AND SCADA-SYSTEMS

JSC “STCD” offers services of programming and parameter setting of industrial controllers and microprocessor-based units manufactured by the leading companies on the nuclear power engineering automation market such as:

- Siemens AG;

- Schneider Electric;

- Alstom-grid;

- ABB;

- Hirschmann — a Belden Brand;

- Моха;

- Rittal;

and many other companies.

PRE-COMMISIONING ACTIVITIES

Pre-commissioning activities include:

- Development of programs, test methods and pre-commissioning activities;

- Equipment and system off-line tests (without impact on the item);

- Integrated tests of automated systems with the adjacent systems;

- Integrated basic function test (with impact on the item);

- Acceptance tests;

- Putting into pilot operation;

- Decisions on technical issues on the basis of the pilot operation results;

- Support during the industrial operation.

|